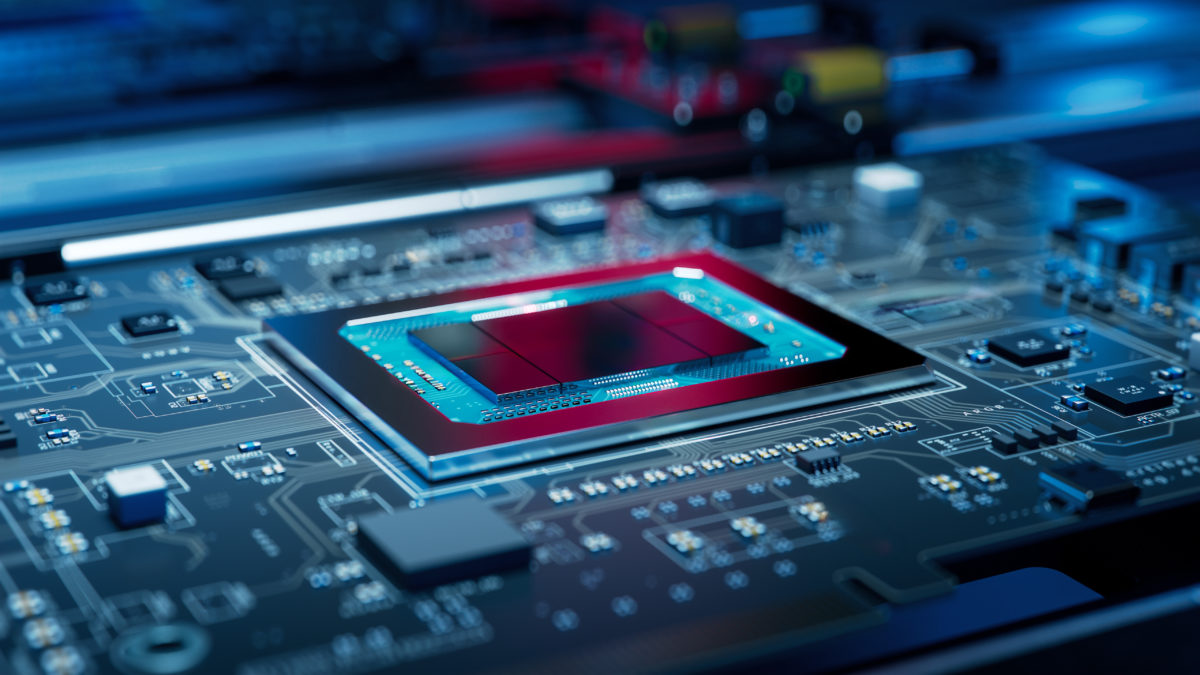

Recent advances in semiconductor manufacturing have led to increases in computational performance at the cost of increasing power densities and attendant thermal management issues. One key to solving these challenges is to reduce the thermal resistance of interfaces in the electronics packaging stack, using advanced thermal interface materials (TIMs). However, existing TIMs often suffer from reliability issues and introduce costly manufacturing complexities. In this SBIR Phase II project, Arieca will build upon our proprietary liquid metal embedded elastomer (LMEE) composite architecture to develop an “ultimate TIM” to imrpvoe reliability and reduce cost of thermal management at scale.

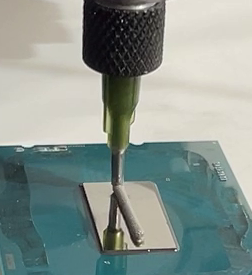

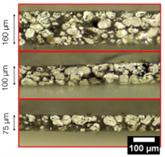

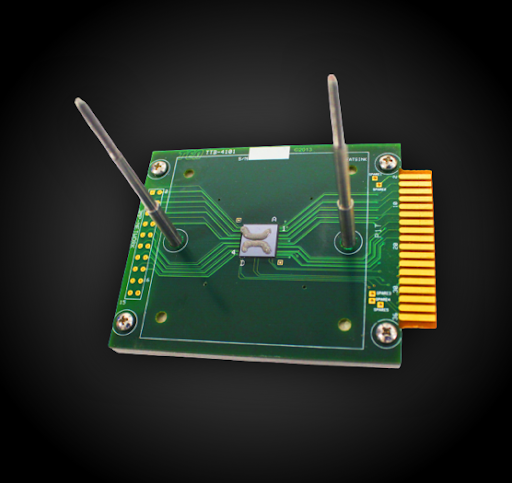

This LMEE-based TIM will outperform existing TIMs by combining the superior thermal resistance of metal-based solid TIMs (S-TIMs) with the mechanical reliability of polymer-based TIMs (P-TIMs) and the high volume manufacturing compatibility of thermal greases. Our strategy in Phase II is to synthesize an LMEE-based TIM that forms a robust bond between the surfaces of the semiconductor chip and surrounding enclosure, maintains a controlled “bond line thickness” (BLT) between the chip and enclosure, and has the necessary rheology for syringe-based dispensing using both augers and pneumatic dispensers. This will involve a comprehensive technical plan that includes materials synthesis, performance characterization, in-package evaluation, and scale-up to high volume production. We look forward to delivering this ultimate TIM to our customers in the integrated device manufacturers (IDMs) and the outsourced semiconductor assembly and testing (OSAT) industry.

For more information please reach out to partner@arieca.com